Audit Compressed Air System

Technical check, Compressor performance analyzer, Energy audit, Leak test

7 steps of a complete compressed air system audit

- Data collection

- Compressor and air treatment technical check

- Compressor performance analyzer

- Room & distribution pipe check

- Leak test

- Operation and maintenance evaluation

- Summary and reporting

Advanced Measurement Tools with Certified Calibration

Power Meter, Flow Meter, Ultrasonic leak detector, Data logger, Analyzer software

Purpose of the Compressed Air System Audit

To get compressor actual and reliable data

- Trusted, actual, reliable data and reports

- Compressor operations data logger

- Compressor ctual energy consumption, Specific Input Power (kW/m³/min)

- Compressor actual capacity, efficiency levels

To find out the potential losses due to inefficient/incorrect systems

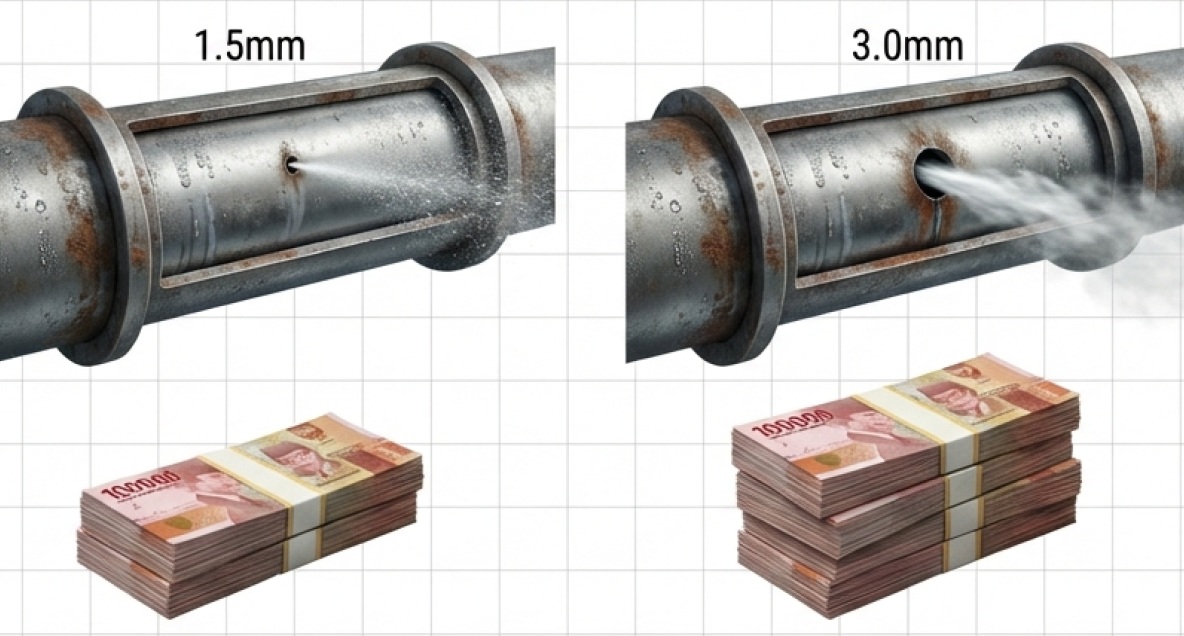

- Find leaks, waste, misuse of compressed air

- Find artificial demand, pressure drop

- Find wrong piping and other accessories

- Find wrong operational procedure

Towards saving electricity and operational efficiency

- To get conclusions and suggestions for improvement.

- To get an overview and calculation of potential savings

- Potential electricity savings of up to 30%

- Operation resource savings of up to 20%

- increased efficiency of compressed air systems

Contact us for consultation

PT. BIOTECH INDO GEMILANG

JKT. 0811 1127 816

SBY. 0811 1126 816

PT Biotech Indo

Gemilang

PT Biotech Indo

Gemilang

_converted.webp)

_converted.webp)